Inspection OF RACKING SYSTEMS AND STEEL PLATFORMS

Inspection - Revision

The inspection is focused on:

-

Evaluating the overall condition of the racking; revealing possible damage to racking components

-

Checking the stability of the racking

-

Checking the constituent elements of all the racking components, primarily safety and security elements

-

Tightening the racks’ bolted joints

-

The completeness and accuracy of the racks’ safety and technical labeling

Scope of inspection:

-

Visual inspection of shelves

-

Attaching inspection labels to the racking system

-

Drawing up an inspection record + familiarisation of the competent person with the final state (all on site)

-

Preparation of an inspection report (based on the minutes drawn up) and its delivery to the competent person

-

If necessary, writing up estimates for eliminating problems and damage

-

Creating missing or new racking labels and delivering them to the appropriate individual for attachment

Repairs

Replacing damaged components

As stated in Czech norm ČSN 15635 listed above, the full text of point 9.7.1 – Replacement of Damaged Components is cited here: “It is not permitted to repair damaged components unless approved by the equipment supplier. Note: damaged components must be exchanged rather than repaired, because it is difficult to conduct effective quality checks for cold-formed material.” We would like to state that we do not consent to repairing damaged components.

Services

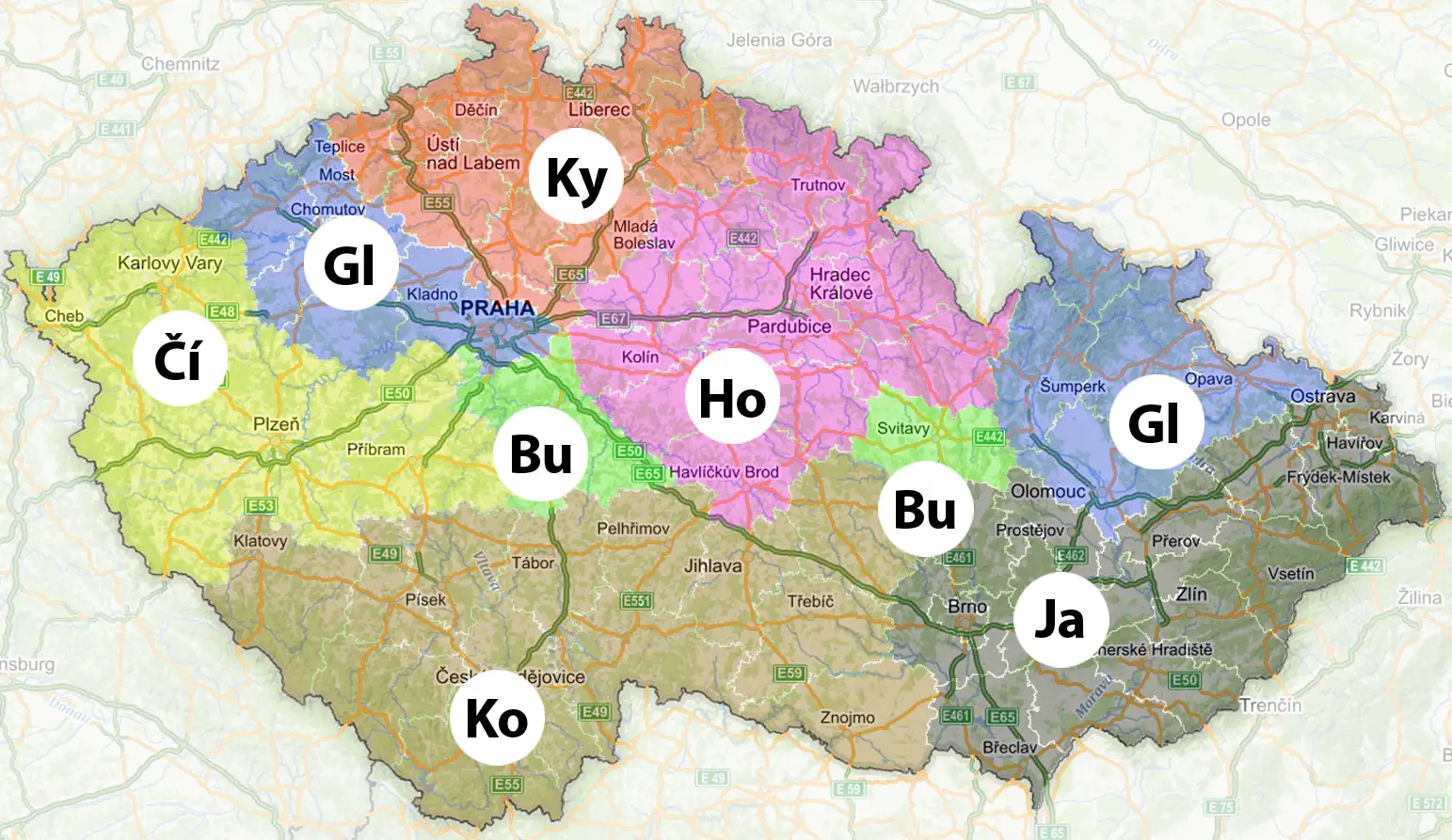

Mapa obchodu

|

Martin Holub | +420 725 429 911 |

|

Eduard Bukáček | +420 727 983 667 |

|

David Kopecký | +420 702 195 708 |

|

Čestmír Javůrek | +420 602 287 702 |

|

Miroslav Glos | +420 606 738 832 |

|

Adam Čížek | +420 720 951 703 |

|

Petr Kyncl | +420 724 269 040 |

Miroslav Glos

Miroslav Glos

tel.: +420 606 738 832

glos@proman.cz

Miroslav Glos

Miroslav Glos

tel.: +420 606 738 832

glos@proman.cz

Petr Kyncl

Petr Kyncl

tel.: +420 724 269 040

kyncl@proman.cz

Martin Holub

Martin Holub

+420 725 429 911

holub@proman.cz

Adam Čížek

Adam Čížek

+420 720 951 703

a.cizek@proman.cz

David Kopecký

David Kopecký

+420 702 195 708

kopecky@proman.cz

Eduard Bukáček

Eduard Bukáček

+420 727 983 667

bukacek@proman.cz

Čestmír Javůrek

Čestmír Javůrek

+420 602 287 702

javurek@proman.cz

Eduard Bukáček

Eduard Bukáček

+420 727 983 667

bukacek@proman.cz

Service assistant:

Markéta Málková +420 725 733 344