Cantilever racks

High weight-carrying capacity

Mechanical durability

Variability

Safety

Fast installation

-

The advantage of this system is its ability to hold stored material with various lengths, shapes, and dimensions while ensuring that individual storage levels have a high load-bearing capacity, the stored materials are clearly organized, and there is immediate access to the stored materials.

-

The most frequent use of cantilever racking systems is to store materials for the metal industry during production or as a storage area for input material at the start of a production line.

-

PROMAN’s racking system comes with a free estimate that includes a project design that takes into consideration the entry area and handling requirements, delivery, installation, the option of inspections, and warranty and post-warranty services.

-

As a matter of course, PROMAN has acquired engineering test certificates at the national level and meets the tough requirements of European norms.

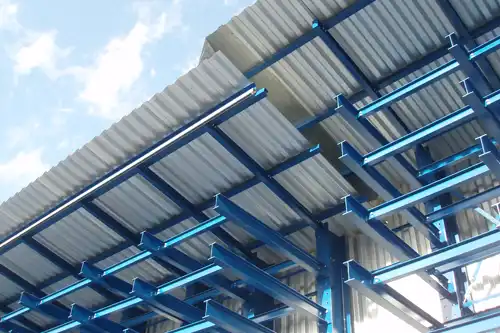

Outdoor instalations

Mobile structures

EU Compliant

Easy to operate

E-SHOP

Take advantage of our range of products in the PROMAN e-shop. Choose basic pallet and shelf racks. You can configure the cantilever rack according to the load/dimensions to your requirements. The system will automatically generate a quote for you. At the same time, you will find a wide range of accessories for pallet and shelf racks in the e-shop.

Technical Details

-

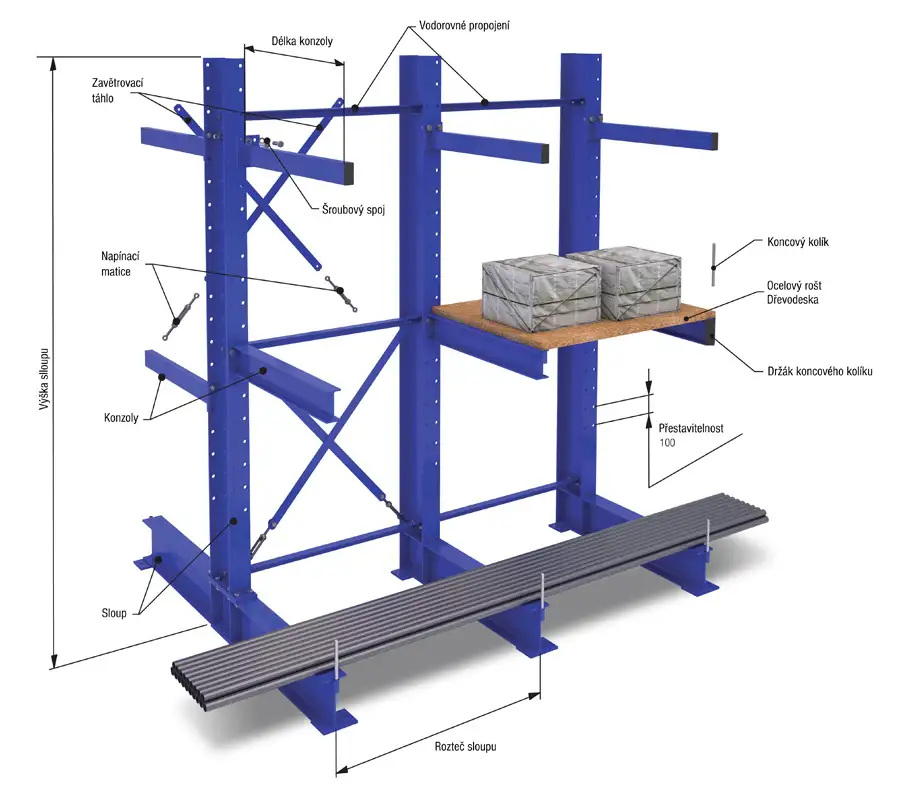

Cantilever racks constructionCantilever racking systems are primarily used for long components that do not necessitate pallets. The components can be stored in bundles or individually. The racks are able to be installed in storage warehouse and factory building interiors as well as in exterior environments; however, they do require high-quality concrete flooring. The construction is designed according to the customer’s requests and requirements for stocking and storing materials as well as the required load-bearing capacity of individual storage levels. Because user requests and needs are varied (the distance between columnss, column length, cantilever console length, the number of cantilever arms, console load capacity, decking for the rack, etc.), each cantilever racking system is approached as an individual unit that is designed according to the customer’s needs. Cantilever racking is a self-supporting, prefabricated structure made from partially welded components. It is constructed of standard rolled steel section that is reinforced using horizontal connections and bracing rods with tensioners.

-

Technical details

The racking quote includes:

- A column with base, including anchors

- Cantilever consoles, including fastening components

- Horizontal and vertical bracing

- Load capacity charts

- The option of supplemental roofing or wall construction, lateral guides for forklifts.

Optional Fittings

- Corner protectors

- Racking side protectors

- Labels for storage locations and racking aisles

- Lateral guides for forklifts

- Crossbeams for pallets and barrels

- Mesh or sheet metal wall panels for the racking

- Panels of metal grating (decking)

- Particle board panels (decking)

- Sheet metal panels (decking)

- Sheet metal for load distribution

-

Cantilever racks accessories

End pins

The end pins serve as a barrier preventing round profiles from rolling off the console. The pins are designed as removable. Only the lugs can be prepared for implementation and the pins themselves may be delivered later as required.

Guide profile

For operation with four-way trolleys, the cantilever racks can be equipped with guide profiles of different heights and designs. The height and profiles used are selected according to the needs of the trolley. The guide profile is anchored to the floor and can be fitted with tapering part to guide the trolley safely and easily into the service aisle.

Cross beams

For material with profiles, pallets and similar, cross beams can be added between the individual brackets for appropriate support of the stored material. The cross beams are dimensioned according to the weight and method of load placement.

Grate/chipboard shelves

For high variability in material storage, steel grates or chipboard can be installed between the brackets. This solution allows you to store everything from long bundles, to pallets or small piece material. To properly design the grate and its support, the future load must be specified in detail.

Gluing of consoles

The storage surface of the brackets may be softened by gluing rubber with textile liner.

Cantilever Racking

Cantilever racks are most frequently constructed with a load capacity of 50 to 2000 kg per individual cantilever console, their cantilever consoles range from 500 to 2000 mm, and the distance between columns is decided according to the length of the stored material and its weight. The column height is generally 2000 mm, according to the number of cantilever console.

Colmuns

The cantilever racking column with base is made from rolled steel section, specifically, IPE beams. The joint between the column and the supporting base is either bolted or welded. On the front side, the columns have openings for attaching the cantilever console; the console is adjustable at a height interval of 100 mm. The column section type varies according to the required load-bearing capacity, height, and number of cantilever console.

Surface finish

The standard cantilever racking finish is intended for use in interior environments – this is paint in the requested RAL color applied by wet spray. For exterior use, hot-dip galvanization is available.

Cantilever storage racks

Storage console is primarily made from IPE, or possibly TR4HR, rolled steel section. The cantilever console is fastened on to the racking column using a bolt fitted through a metal flange. At the end, they are equipped with a catch for an end pin to protect against rolling material.

-

Download

Photogallery

Why choose PROMAN

Complete Supply from the Proposal to the Installation and the following Service

We provide our customers with the offer including draft of the racking solution for free.

Professional Service in Czech Republic and Abroad

PROMAN s.r.o. is one of the most distinguished suppliers of all types of racking systems on the market and is able to respond in a very flexible way to any and all of a client’s needs.

Our Experience Guarantees your Satisfaction

During that time we have made a trunover of more than 40 bilions of Czech crowns.